Efficient organization of production processes is one of the key factors determining the competitiveness of modern industry. The task of scheduling machines, people, and resources quickly becomes a highly complex challenge. Addressing such problems requires advanced mathematical methods and specialized software tools that can analyze countless possibilities and identify the most effective solutions. A successful collaboration between the company ScheduleOpt and researchers from CIIRC CTU in Prague has led to state-of-the-art results in solving famous scheduling problems studied for decades.

The joint work of CIIRC CTU and ScheduleOpt with the new advanced Constraint Programming (CP) solver OptalCP has just been published in the prestigious international journal Computers & Industrial Engineering, ranked among the world’s top in operations research according to Google Scholar.The study attracted significant attention from the research community even before its official publication. In March, for a while it became the most downloaded article in its category on the SSRN preprint platform in the last two months. The research teams focused on a long-standing challenge: not just finding good solutions for scheduling problems, but being able to prove that the solution is the best possible one. This step is often the slowest and most demanding for existing solvers.

So what is this innovation about? While mathematical solvers might seem abstract to most people, they are the hidden engines behind many of today’s decision-making in complex planning and scheduling tasks in factories around the world. In particular, Constraint Programming is a powerful approach for tackling highly complex optimization problems in scheduling such as assembly line productions.

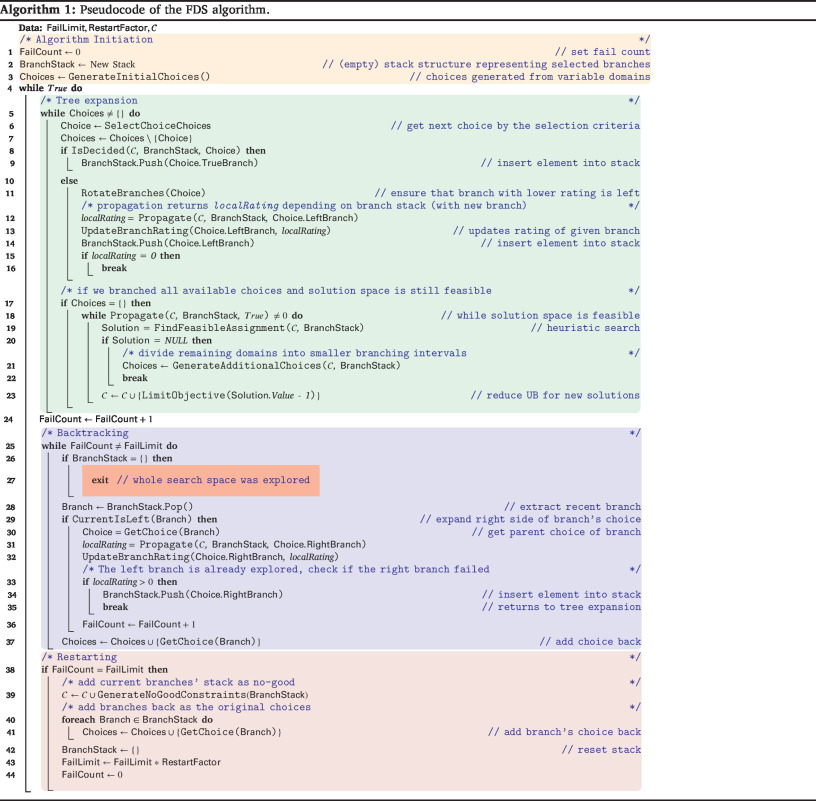

Instead of manually defining each step, rules and requirements — called constraints — are specified declaratively and the solver automatically searches for solutions that satisfy them all.

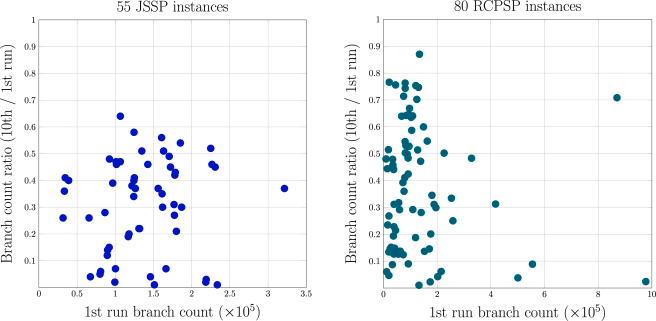

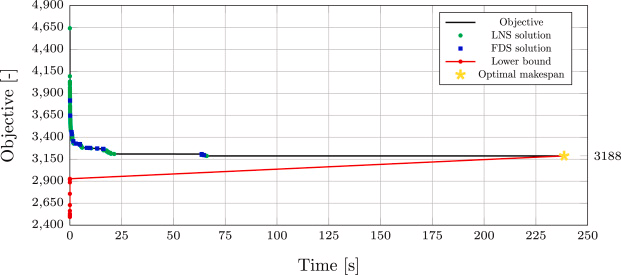

In this particular research, the focus was on the improving the solver’s ability to guarantee optimality of solutions — a stage where modern solvers often spend most of their computational effort, as proving optimality can be harder than finding a good solution.By integrating a reinforcement learning framework based on Multi-Armed Bandit algorithms, a roughly two fold speed-up in optimality proof times was achieved compared to the previous version of OptalCP, outperforming the current version of IBM’s market-leading CPOptimizer.

The impact of this work has not gone unnoticed. At the end of March, the preprint of the research gained significant attention on preprint platform SSRN, ranking top 10 in multiple categories over the last 60 days and even topping the “OPER: Discrete” chart. Recently, the research was officially published in the prestigious journal Computers & Industrial Engineering, which is currently ranked #3 worldwide in the Operations Research category by Google Scholar.

This achievement highlights how ROBOPROX project facilitates the cooperation of academy with industry, combining cutting-edge algorithms with real-world solver technology delivering improvements in complex problem-solving.

The impact extends beyond theoretical insights. Smarter and faster solvers, such as OptalCP, can have a direct impact on how production systems are planned in industry worldwide, from assembly lines to logistics and beyond. The ROBOPROX project has thus once again demonstrated the value of connecting academic research with industrial applications, opening the door for real-world improvements in efficiency and competitiveness.