Imagine managing a complex production environment with multiple shifts, sequence constraints, and varying resources, all while ensuring the smooth flow of operations across numerous production lines. This was the challenge that Artelys tackled in collaboration with Toyota Motor Europe. In a recent seminar, Hugo Chareyre introduced how Artelys developed an advanced scheduling system to optimize post-production operations in Toyota’s workshops across Europe, revealing the intricacies of real-time operational planning in the automotive sector.

Chareyre’s talk explored how the scheduling problem faced by Toyota differs from traditional scheduling models like the Resource Constrained Project Scheduling Problem (RCPSP). With added constraints such as preemptive breaks, shift changes, and specific sequence requirements, this scheduling task requires a more sophisticated approach. Moreover, the system aims to meet multiple objectives, from minimizing late tasks and vehicles to improving efficiency and ensuring worker safety.

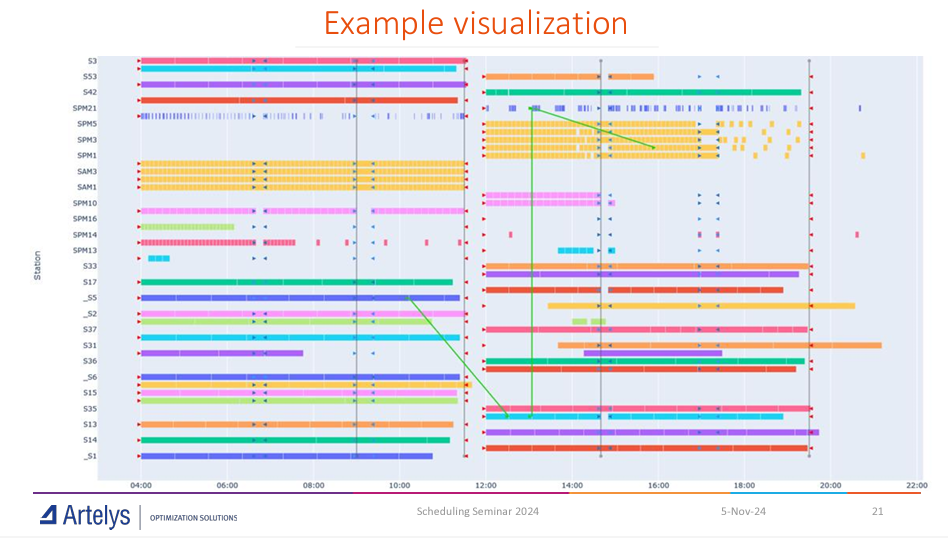

By working closely with Toyota, Artelys created a micro-service solution that automates and streamlines the scheduling process. This real-time decision-aid tool, built using constraint programming with Fico Mosel and optimized by the Artelys Kalis solver, replaces manual, time-consuming scheduling methods, delivering faster and higher-quality solutions across Toyota’s European workshops.

For thosewho want to learn more about this innovative scheduling solution, the PDF download and seminar recording are available.

Are you interested in other similar seminars? Then don’t hesitate to follow the Scheduling Seminars website so you don’t miss any more events. Here you will also find recordings of past seminars and other interesting information. We look forward to seeing you at the next seminar!