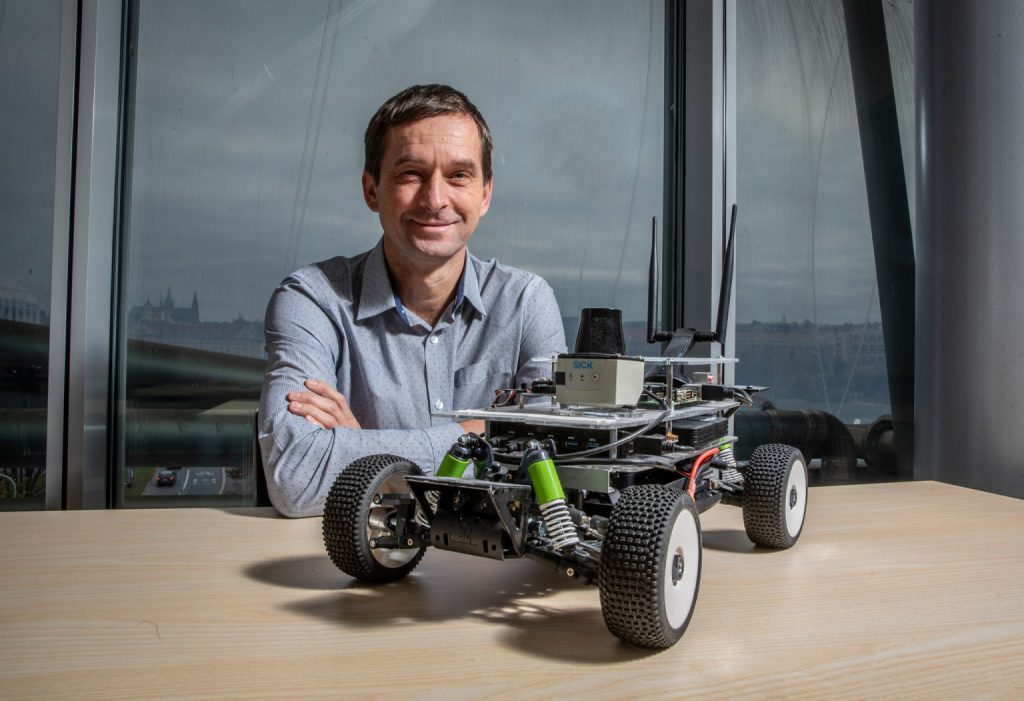

The leading Czech Economic Daily “Hospodářské noviny” interviewed the ROBOPROX Principal Investigator Zdeněk Hanzálek. The article was published in a special supplement of HN Strojírenství.

Written by Helena Dostalová, 6 December 2023

We’re at a crossroads. Either we go the modern route and robots become a common part of production, or they become exotic components. Then the Czech Republic will unfortunately be relegated to the level of cheap assembly plants, says Zdeněk Hanzálek, head of the industrial informatics department at the Czech Institute of Informatics, Robotics and Cybernetics (CIIRC), which is part of the Czech Technical University in Prague.

What are companies currently dealing with in the area of digitalization?

I would say digitalisation as such, because they don’t have the data in computer format. There are people working in companies for years who have all the data from production planning to orders in their heads. Then they leave and the system stops working because this particular person is missing, who may not even have been aware of his function, did it selflessly and his progress is not recorded anywhere. Plus, it’s piles of data that are complicated to enter into the computer. Therefore, companies have to deal with digitisation already in terms of automatic data retrieval and conversion. We encounter this very often. To ensure that the data is in the right format and is present in the company at all. Larger companies are better at this, smaller ones did it first in the form of pencil and paper, then Excel, but even there they don’t have a lot of information. I think it is the overall digitization that is preventing more momentum.

And is that true for small and medium-sized companies, or is it also true for larger ones?

We have a number of engineering companies with up to 200 employees where we are always dealing with these problems. There are still relatively few technical-management positions in these companies. It is difficult to find IT workers. There is a shortage of people to keep the data in an adequate state. This is a very desirable skill segment and it is true that the engineering industry is not as attractive as the big IT companies. I think there is no easy solution and it will be a long-standing problem.

You are dealing with manufacturing optimization. What has changed over the years?

We are moving towards mass production falling away and custom manufacturing coming to the fore. So a lot of things are changing. When a product took two years to produce, people were able to optimise it. Now it changes two or three times a day. In addition, techno-managerial positions such as various planners and technologists have disappeared. Often there is only management and labor in companies. So it very quickly becomes the case that production is inefficient because it is poorly prepared and burdened with unnecessary work.

What is the biggest issue in this area?

In manufacturing, two requirements are fighting – deadlines and the number of possible rebuilds of production lines. The optimization task is to find the best plan that will satisfy all the requirements or say that it does not satisfy them. This is the scheduling task of finding the right order of tasks. When you have ten thousand operations per week in a factory, no one can move numbers around in Excel, but an algorithm can create the optimal plan and group them together.

How important are robots?

In the future, you will either have manufacturing that is very hi-tech and robots will have a place in it, or you will do without them – but then there is a danger that companies will move away from us to the East, where they can find cheaper labour. So we have no choice but to do hi-tech manufacturing. And businesses know it. They will have to put a robot in place of a human because it will do the physically demanding or dirty work. There shouldn’t be people standing by hot furnaces anymore. Repetitive production can also be handled better by a robot.

Does this also apply to smaller companies?

When a small company gets a robot, it is not completely satisfied with it because it lacks someone who can take care of it adequately. Sometimes the problem is that the company doesn’t produce as much repeatable work. If you’re a smaller company with two robots, you’re also not as attractive a customer for their suppliers, perhaps even in terms of maintenance. And it’s also more expensive for you to operate. Which is not just related to the factory, but also to the country. The more robots there are in a country, the more integrators, suppliers and so on. So we’re at a kind of crossroads where we’re either going to get caught up in hi-tech, including robotics, which is going to take off even more, or it’s going to be more of an exotic component.

I thought we had passed this crossroads and were on the road to progress.

According to various studies, the Czech Republic is doing relatively well in the number of robots. But if you take the average factory in the Czech Republic, that’s not the case. In a company with around 200 employees, everyone talks about robotization, here and there someone introduces something and tries it, but I haven’t seen any great success so far. I haven’t come across a recent case where I’ve heard that a small company has bought ten robots and is happy with them. Maybe the information hasn’t reached me, but I’d say we’re still in that transition. It’s more likely that a large car company will buy a new line of robots, which will increase the total number of robots in the Czech Republic, but I don’t know if that can be considered a success on our road to robotization.

And do you think robots are a necessity for companies, or can they do without them for now? Because getting a robot is not a guarantee of success.

I think that, with salaries rising and the price of a robot coming down significantly, a robot is more reliable. You’ve seen, for example, the loss of manpower in covid. I don’t think we can do without them. There will have to be some proportion of robots in companies and a greater level of automation and robotization to be competitive.

Can you summarize the benefits for smaller companies as well?

Ease of work and relief from complex tasks. For the employer, the robot is more deterministic, some workers do the job for ten minutes, others for 20, the robot still does the same. The robot doesn’t get sick, you don’t have to persuade it to work overnight. If there are enough robots around, it makes deliveries and maintenance easier. It’ll be more profitable to deploy it. Along with that, of course, quality is expected to increase and money will be saved.

So now robotics will be directed towards smaller companies?

Absolutely. We have classic areas where robots are deployed, such as welding lines in large factories or robots that move something from place to place. Now it’s about finding other areas where people can be replaced by robots. It won’t work everywhere, but more routine operations that are the same across multiple companies will be more viable for contractors to tackle. They will be able to deploy entire solutions quickly and with great reliability.

What lies ahead for large companies that already have robots, are digitizing or optimizing?

In manufacturing, a digital twin that simulates production in 3D is now very much in use. When a production line is deployed, there are long discussions between directors, half a year of concrete pouring and a week left for programming. Which puts a huge amount of stress right at the end of the process, and integrator companies don’t have the money to run the robots in-house and spend a year debugging them. The big advantage is that the process can be simulated.

But the digital twin is not such a novelty.

It didn’t work so well before. Online programming was promoted, where everything was done on the spot, but nowadays more and more offline simulation is used. Energy-efficient production is being done – when a robot works very fast it consumes a lot of energy, when it works very slowly it does too. So you need to optimally choose how fast it should move, which has an impact on the following operations and entering collision zones. There are many things that the programmer on the spot can’t even do well enough because it’s too complex, there are many combinations and alternatives. This way you have more time and you can use algorithms that guarantee more efficiency. For example, with respect to energy.

You are also an educator, how do you see the topic of digitalization and education? Can we take advantage of the opportunities that robots bring in the current education system?

I think that society’s relationship with crafts and technology must be restored. The prestigious profession until now has been to sit at a computer and operating a machine is almost seen as dirty work. I don’t think it’s well grasped. Which has to do with attractiveness. Apprenticeships no longer have to be a dumping ground for those who don’t get into grammar school, but can have prestige. And it should start from primary school, not deal with work education with PowerPoint presentations so that kids don’t accidentally cut themselves in the workshop. We’re looking down on manual labor. I also see the fault of the companies here, that they have not managed to popularise their industry sufficiently.

Isn’t it a problem in your field that the school system doesn’t allow a student to make a mistake?

That’s what I’m not happy with. In schools, we focus on frontal teaching. I’m sure there is a proportion of project-based courses, but I think it’s very small. The life of a technician is such that he observes a problem, finds out what’s wrong, fixes the thing, tests it and puts it into operation. That doesn’t happen much at school. Someone is comfortable with frontal teaching, learns what Vrchlicky wrote, and gets an A. But in practical life, they don’t really need it. A programmer’s work is created under his hands, it’s based on the fact that he can make mistakes, try things. Schools aren’t very much like that. It’s either perfect or it’s bad.

Speaking of education, you managed to get the Roboprox project funded by the Top Research call in the J.A. Komenský Operational Programme. Can you tell me more about it?

The project will involve about 180 researchers from six units of the Czech Technical University in Prague, Brno University of Technology, Brno University of Science and Technology in Ostrava and ZČU in Pilsen, working on topics in the field of robotics and advanced industrial production over a period of five years. We have very ambitious plans and we want to help the Czech and European economy transition to flexible, environmentally friendly and competitive manufacturing. Mathematical modelling, data-driven approaches, simulations, optimisation algorithms and formal methods are gaining wide popularity in industry. However, there is a lack of appropriate engineering tools, simply because there are no suitable underlying concepts, linkable models and high-performance algorithms. This opens up a clear opportunity for our project to research, develop and introduce innovative research methods into industry.

If a company wants to succeed in the competition, it must increase efficiency, especially with regard to the level of automation, the materials used, the autonomy or flexibility of the robots, production schedules and volatile energy prices. Complex multi-dimensional optimization problems with many conflicting objectives and complex constraints need to be solved. For example, customers increasingly demand smaller batch sizes, so production lines must strive for high throughput with fast automated reconfiguration.

We have selected our best researchers for the project, who have verifiable results, well-equipped facilities and core competencies in robotics, automatic control, materials engineering and industrial informatics.

You are also involved in autonomous vehicles, what is the current status?

Some people feel that you should jump right into robotic cars that will take you to the airport and drive back without a driver. I think that’s the music of the future. Although there are already some early, as yet unrepresentative cases. What is representative, however, are autonomous systems that fill in where the driver is unreliable or might react badly. Certainly in the near future, cars can drive for us on the highway in traffic without us holding the steering wheel.

The prototypes we create in collaboration with different companies are often related to guessing the situation around the car, for example a damaged road, a sandy road where fast driving could cause the car to skid. So we use lidar, radar, cameras and various sensors to assess the situation around the car.

Interesting developments are taking place, for example, in advanced parking systems, where you drive up to a parking house, hand over the car and it parks itself.

Photo: Honza Mudra

What project are you currently working on?

With TÜV SUD, we are conducting research at an airport in the Czech Republic that is designed for car testing. On a road with good horizontal markings, we are testing our Automated Lane-Keeping System (ALKS), which keeps the car in its lanes while keeping its distance from the car in front – adaptive cruise control. We are currently testing two manoeuvres. One is a cut-in manoeuvre, where another vehicle comes between the one we’re driving and the one in front. The adaptive cruise control then has to cope with the fact that the distance has changed by leaps and bounds and has to slow down to maintain the distance and speed chosen by the driver. The second is the cut-out manoeuvre. Imagine that two cars are following each other and a car suddenly stops in front of them that the system in the other car cannot see. The first car swerves and the second car has an obstacle in front of it at that moment. We also test in different weather conditions. There is already a first procedure within the European Union for the certification of ALKS.

What other functions could be extended on Czech roads?

Traffic jam driving, for example. Many accidents are caused by talking in traffic, blinking on the mobile phone, losing attention and failing to brake in time. I think assisted driving is relatively close, especially where the infrastructure matches it – a pre-defined highway, where the profile is well mapped, the highway has crash barriers, and the car has something to grab onto in its perception of its surroundings. These are things that can be automated well.

Is it realistic that an autonomous car will ever drive through Prague?

If you mean completely driverless, I can’t say exactly because there are many factors. The driver’s assertiveness must also be taken into account. If a van unloading goods stops in front of him and there is a full line next to him, he will safely pass the van even at the cost of breaking the rules, but he will not create a traffic jam behind him. The autonomous car is not programmed to cross the full line, so it will stay stationary and other cars will honk at it. If there is a driver in the car, he or she takes over and the situation is resolved. That’s why I think we’re talking about a driverless car in a very futuristic way. What is going to be coming in the next five years is mainly advanced driver assistance systems that can save drivers’ lives or significantly reduce the risk of a crash. And that’s in increasingly difficult weather conditions.